Starting out as a ‘lockdown project’, the Weighay modular bale scale has helped to bring consistency to the conventional bale market

With the poorer crops seen in second and third cut grassland, and a reduced amount of straw, growers and contractors have focused more on weight consistency in conventional bales. That’s according to Gordan ‘Sid’ Smith, the man behind the Weighay system, providing service and support for Bale Baron UK.

Weighay consists of a weighscale, either fitted on the baler chute or on the intake of a bale accumulator. A specially designed skeleton chute can also be supplied to make the fitment to the baler easier. Each bale is weighed multiple times, taking an average of the weight across a preselected number of bales and feeding this data into an ECU that automatically adjusts the hydraulic pressure of the baler to maintain the desired weight.

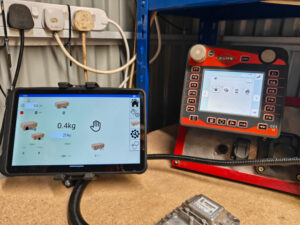

Through the in-cab screen, operators can monitor and adjust the target bale weight, as well as seeing the average bale weight and total weight across the yield; bale counts and bales per hr; flakes per bale to maximise ground speed; and the hydraulic pressure and plunger speed.

“It was an idea I had during lockdown,” Sid explains. “A number of Bale Baron customers had enquired if a bale scale existed, and following some research, it appeared that nothing was available for accumulators. I’ve been working with large square balers for 40 years, so I used this experience to design one.”

He worked with local agricultural developer Solsteer to build the software and launched the first model in 2021. Following two years of testing in the field, the Weighay system went into full production in 2023.

The load cell, strangely enough, comes from a drink vending machine, with a stainless steel cover that presses down over four strain gauges to measure the weight. As part of the design, a small metal ramp lifts bales onto the scale so that other bales cannot influence the readings by pressing against and taking some of the weight.

Always learning

Always learning

The scale is rated for up to 100kg, ideal for conventional bales. “Most set it for around 20kg,” Sid says. “It isn’t just about consistency for haulage, but also consideration for the end customer. A lot of these bales will end up in equine yards, and someone must lift and move these.”

It’s a modular plug-and-play system, delivered as a complete set that takes around four hours to fit, and can be used with almost any conventional baler. All optional extras can simply be plugged into jack plugs on the main harness.

The only requirements are hydraulic density control on the baler and a flat surface to mount the scale. The system is Isobus compatible so it can be plugged into the Isobus socket, or, if another Isobus machine is being used at the same time, it can connect via the nine-pin diagnostics port. For tractors without Isobus, a WiFi module is available that wirelessly feeds information to a tablet in the cab.

To limit maintenance through the system’s life, the wiring harness has been designed in three sections, meaning that users will not need to replace the full harness if there is an electrical issue.

It requires minimal calibration. Sid recommends that users use their own accurate scales to weigh a bale and then place the same bale on the Weighay and adjust the settings with the terminal to match the weights. The system has a reported accuracy down to 0.1kg when correctly calibrated.

“A big advantage to the software is that it is constantly analysing the data it receives, reviewing the results of any adjustments and dialling in the pressure changes,” Sid says. “The first time out with the system, it might over- or under-adjust the hydraulic pressure when crop conditions change to maintain the weight and readjust itself to find the correct settings. After a few hours, it will finetune these settings and make smaller, more accurate changes.”

Users can adjust nearly every setting to ensure that they get the desired results. As well as the target weight, they can set the hydraulic adjustment sensitivity and response to make more incremental adjustments to the pressure. The number of bales per average can be shifted, depending on variations to both the weather and the crop. It’s also possible to set the hydraulic pressure, meaning the system works to maintain this regardless of conditions, rather than basing it on the bale weight.

Through the field tests, software filters have been built in to account for rogue readings. If a single bale weighs more than 25% over or under the average, the system will automatically ignore this and will not make any changes until the number of bales per average has passed over the scale. This minimises the number of bales not meeting the specified weight, while also limiting the risk of a significant adjustment that throws off the weight of the following bales.

Options, present and future

Options for the Weighay system include compatibility with the HarvestTec moisture meter technology. Taking readings from the star wheels, live information is shown on the screen, with the ability for the operator to set upper and lower limits.

A bale length monitor has also been integrated. The terminal indicates both the current bale length and the last bale length measured, with a settable alarm for bales outside of the desired specifications.