At the end of 2024, Huddersfield-based powertrain provider and systems integrator, Lancereal, announced a management buyout that would see founder and director Nick Hampson retire while his daughter, Laura, and engineering director Rob Yorke stepped into co-managing director roles.

The change comes as the company aims to take big strides into the agricultural market, seeing this as a logical next step as the industry shifts to increased levels of electrification and automation.

But that’s jumping ahead. Nick founded the business after working his way up the ranks of David Brown. He saw a need across both industrial and agricultural markets for a middleman.

A company that could source powertrain components, combine them – occasionally with fabrications to ensure that each part fit together – and then provide UK-based support.

“It was a two-person operation for a long time,” explains Rob. “Nick handled sales, procurement and any engineering that was required, while a single employee handled administration.”

Laura adds that as the business was initially run from Nick’s home, it meant it often became a family operation. “I can remember helping him pack centrifugal clutches to be sent off to customers.”

As the business developed, Nick secured distribution agreements with global manufacturers, offering both off-the-shelf and bespoke gearbox solutions, clutches and braking set-ups, and PTO systems.

In 2011, Rob joined the business, taking on a design engineering role, with Laura following in 2014. By this point the company had expanded and taken up residence in an old textiles mill near Huddersfield.

“Over time, we’ve expanded our area within the building,” says Rob. “Initially, the business was run from the offices and a small workshop, with the rest of the building rented out to other local businesses, which we’ve gradually brought back in house to increase our stockholding and machining capabilities.”

An option for start-ups

As Lancereal has grown, its role within the supply chain has developed from simple procurement to something more integral to product development.

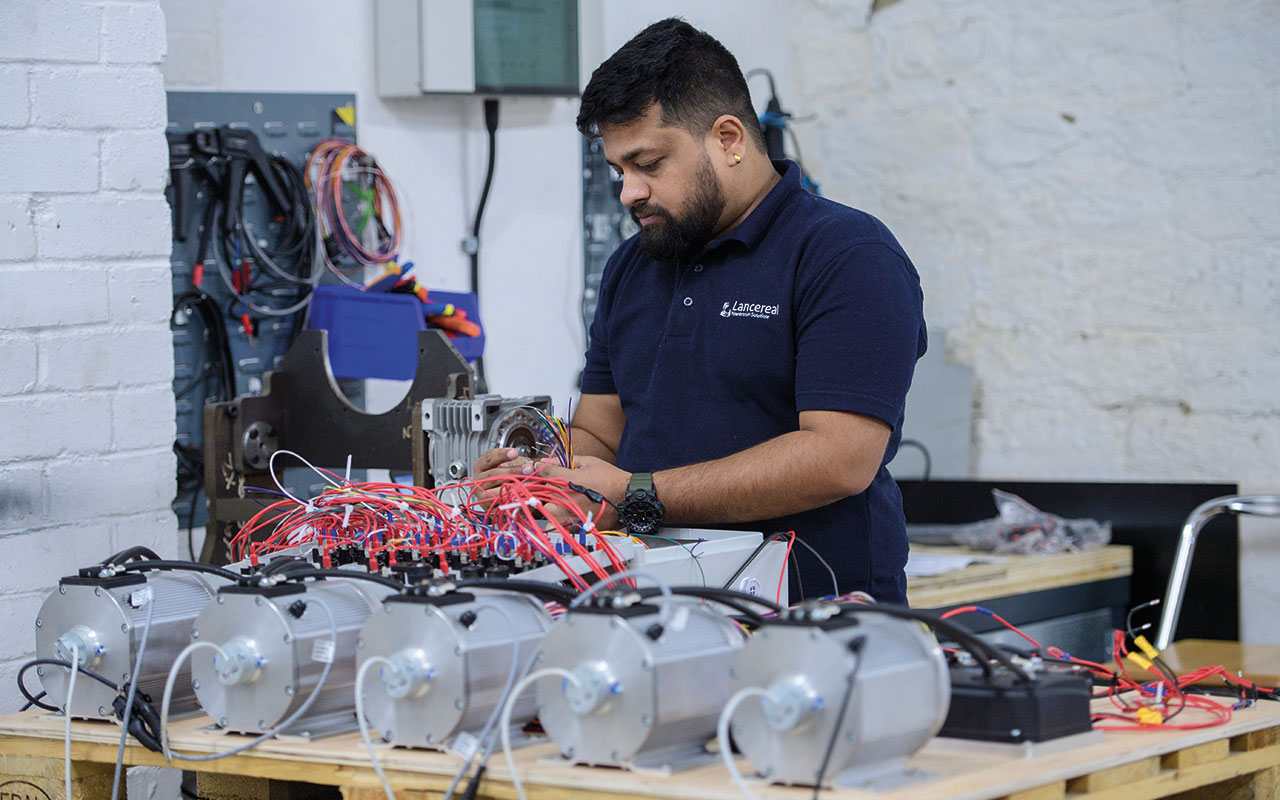

Rob says they work closely with companies of all sizes – from JCB, where they helped to source and integrate electric drives into the powertrain of the company’s electric Teletruk portfolio, to start-ups developing new products for commercialisation.

“One advantage we have is scale,” Rob adds. “We can hold stock where our customers might not be able to, and supply components on a just-in-time basis to suit their production schedule. Because we work with a number of different suppliers, we can find the best solution at the right price point.”

This means Lancereal is often brought in at the early stage of design, enabling it to advise companies on the best solutions for their needs. This can be a single component such as a centrifugal clutch or a gearbox, a mechanical driveline or a complete electrical powertrain.

Sales manager Matt Hanson says the range of products available also enables Lancereal to scale the complexity of its solutions to the end-user. “There has to be a reason to shift from one system to another, or to add an extra level of complexity. We can help our customers find the right balance.”

With so many products available to the company, and the individual needs of each customer, the team now see Lancereal as a full solutions provider, rather than a dealer for specific brands.

This is backed up by the CNC machining facilities on site, which enables bespoke parts to be designed, made and tested, based on drawings from the customer, to ensure that the full drivetrain works as desired.

“We also have the benefit of being UK based,” explains Laura. “So, if a component fails, we’re on hand with support, which in most cases means parts do not have to be shipped back to the manufacturer.”

One of the companies to benefit from this early intervention from Lancereal is EXVO; an Irish startup that has developed an electric skidsteer.

The fact that Lancereal could supply the required components, while also being a small enough company to work around the strange hours that are common among startups, made it an appealing alternative.

As well as providing electric motors and planetary gearboxes, built in-house by Lancereal to meet the size and specifications of the skidsteer drivetrain, EXVO also brought the company on board in an advisory role, using its experience in procurement to ensure that the components matched the product.

EXVO’s EX2 skidsteer is now due to go into full production, with Lancereal remaining on board to provide the drivetrain components as orders come in.

The future is electric

EXVO’s successful collaboration with Lancereal is indicative of the direction the company wants to take going forward. Rob, Laura and Matt all believe the biggest opportunities within agriculture lie in electric power.

“This doesn’t have to be fully battery-powered machines,” Matt explains. “The responsiveness and accuracy of electric mean our motors and drivelines could be integrated into implements hooked up to traditional engine-driven equipment.”

Over several years, the company has built stock levels of motors, transaxles, electric wheel drives and geared motors to suit the needs of manufacturers and startups. These are offered alongside the more traditional drivetrain components.

Laura says that as more sectors move to electric – with construction leading the way due to more stringent pollution and noise legislation when working in cities – agriculture is bound to follow suit.

“There is more pressure than ever, from a policy level and down, to manage tailpipe emissions, and while not every solution will be suited to agriculture, as battery technology develops we will see it more and more.”

Since January 2024, Lancereal supplies and supports a series of control systems to manage electric components, initially from the cab, with a review to full remote control and monitoring. These include Canbus modules, power converters for charging modules and even in-cab displays.

Alongside this, the company has opened its doors to provide in-house training should customers require it. This can include standard practice, including fitting and repairing the components, to more theoretical training on how new systems can be used within equipment.

“A lot of our work is with engineers; either larger teams within established manufacturers or individuals in startups,” says Rob. “We can have them here, learning in our workshops, or move on site to advise.”

While electrification and automation are believed to be key drivers for the company in the future, they all agree that the demand is still there for the standard drivetrain components.

“The business began with centrifugal clutches, and these are still core to our offering,” Laura says.

“We recognise that these original drivelines aren’t going to go away overnight. There is still a demand for new systems and maintenance, and we’re currently looking at expanding our team to ensure that we continue to offer the same service to new and existing customers alike.”