French direct drilling specialist, Novag, will introduce a new mid-range model of its T-ForcePlus seeders. The 750 offers working widths of 7.2m or 7.5m, slotting between the existing 650 and 850 machines and available to order for the 2026 season.

It’s the first machine to feature the company’s IntelliHead system, a new generation of distribution heads that offers a larger diameter and a newly developed section control function. According to the company, it will not only shut off individual rows automatically to avoid overlap, but also monitor seed flow for complete control of product distribution.

The IntelliHead will be available for all Novag machines over 6m from 2026.

Back to the T-ForcePlus 750, and it has a redesigned frame with a three-part folding system, as well as a new seed and fertiliser tank. According to the company, this frame is easier to assemble, enabling Novag to speed up production and control costs.

There’s a choice of 30 or 36 coulters on the 7.2m version for row spacings of 24cm or 20cm, while the 7.5m machine is only available with 30 coulters for a 25cm spacing. The T-SlotPlus coulter cuts an inverted T into the soil to separate sowing and fertilisation, with IntelliForcePlus pressure control for a downward force of between 100-500kg.

It requires around 300hp upfront for a working speed of 12kph and is designed for drilling seasons of around 1,000ha.

A novel approach to fieldmice

A novel approach to fieldmice

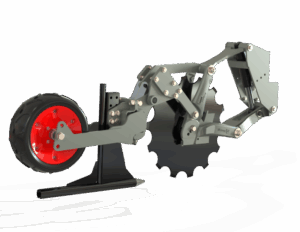

Another novel addition to the Novag range is the IntelliFox, which will debut at Agritechnica. Designed to tackle undisturbed fieldmice burrows in no-till scenarios, it can be fully integrated into existing T-ForcePlus drills. A 57cm serrated cutting disc is mounted behind the coulters, followed by a 5cm diameter torpedo that runs through the ground at depths between 10-20cm.

From the torpedo, rodenticide is applied – using an additional tank on the drill – metered automatically based on the distance travelled. A large, rear roller closes and consolidates the soil.

Like with the drill coulters, the ground pressure can be adjusted from 100-500kg using the IntelliForce system.

According to the company, the power requirement is just 10-15hp per row, and the system can be retrofitted to existing drills. A standalone version of the system will be offered from 2027, and the company is currently undergoing the approval process with the Julius Kühn-Institute in Braunschweig.