At Lamma, grain handling specialist McArthur BDC will hold demonstrations of the Bühler Spark colour sorter.

“We’re looking forward to showing Lamma visitors the superb engineering behind the Bühler Spark,” said Scott McArthur, project division director, McArthur BDC. “It’s built to last, easy to use, and designed to deliver consistent results on farm.”

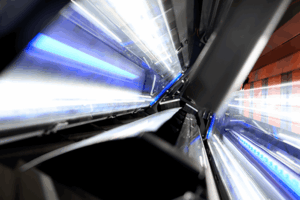

It’s controlled via a touchscreen control panel, enabling real-time monitoring. Each chute has two dedicated cameras to target unwanted grains.

In addition, it features self-cleaning mechanisms to keep the machine running efficiently.

“When designing a colour sorter into a grain plant, no matter the size, it’s vital to work with an experienced integrator who understands both what you want to achieve and what’s possible within the constraints of the project,” Scott added. “Every detail matters to ensure the sorter performs reliably on farm.

“Our grain cleaning and sorting specialists design every installation around the farmer’s needs – from achieving the necessary throughput, meeting crop specific specifications to the seamless integration of the colour sorter with other processing equipment. There is also a focus on the practical details too, like easy access for calibration and day-to-day operation.”

It uses the cameras and sensors to recognise discoloured grains, weed seeds, ergot and other unwanted material. According to the company, it will provide a more uniform grain sample, leading to better prices while minimising the risk of rejections or deductions.

Those who want to see the Bühler Spark in action can visit the McArthur BDC stand (8.410) at Lamma.