While farmers in Britain were showing little interest during the early stages of crawler tractor development, the reaction from the British army was much more enthusiastic.

The fact that a tractor on crawler tracks could be driven in difficult ground conditions attracted the attention of senior military officials who wanted to develop an armoured vehicle that could cope with mud, steep ground and even cross the battlefield trench systems.

See also: Whatever happened to… the first driverless tractor?

They organised a high priority development programme codenamed ‘Landship’, and the result was the world’s first army tanks, an effective weapon during the later stages of World War 1.

For the engineers working on the Landship project, the obvious place to find the track technology they needed was America’s tractor industry, and several American tracklayers were imported for use in an evaluation programme.

One of the tractors was a Bullock Creeping Grip 12-20 model, made in Chicago by the Bullock Tractor Co, a company that had been established in about 1913 from the remains of a previous tractor manufacturer that had been forced to call in the receiver.

Unusual design

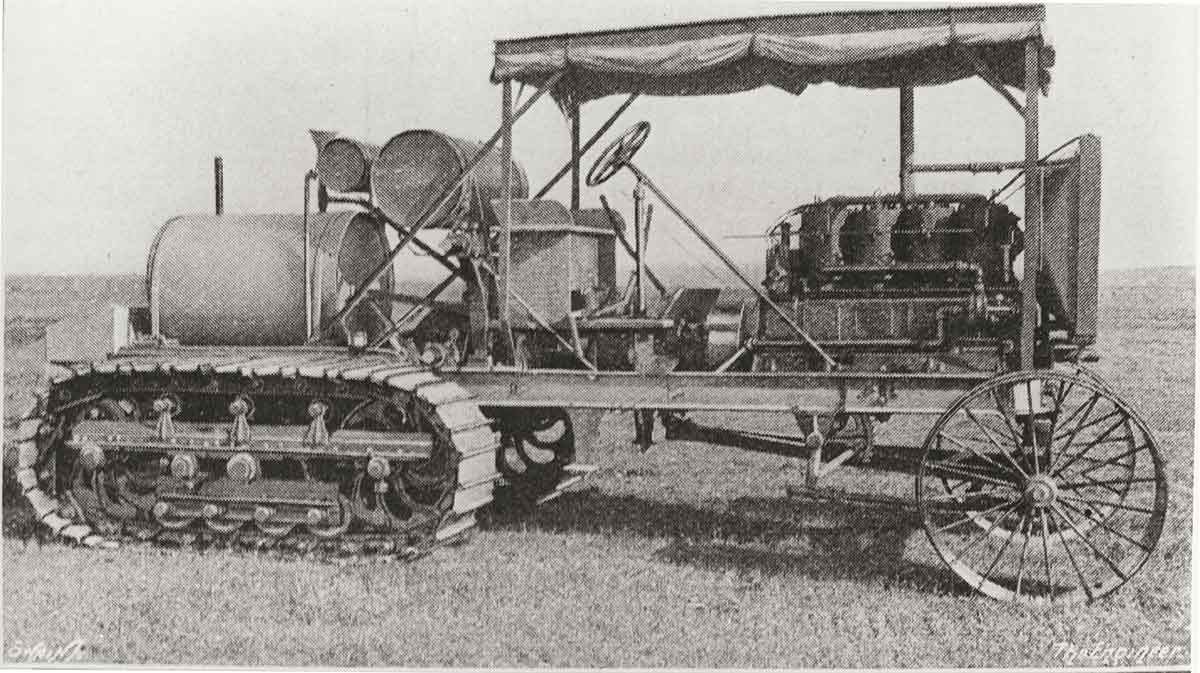

The 12-20 tractor, introduced in 1916, had some unusual design features including a steering system that was controlled by track brakes and clutches instead of one or two wheels at the front of the tractor.

Before the 12-20 arrived, most of the tracklayers used wheels to provide the steering action, and they included the previous Bullock Creeping Grip 35-50 model, the first Bullock company tractor.

Using wheels to steer a heavy crawler tractor must have been inefficient, especially on a wet ground surface, with problems including lack of accuracy and poor manoeuvrability, and the wheels at the front also extended the overall length of the tractor.

The Bullock company was one of the early pioneers of using brakes and clutches for steering, and on the 12-20 tractor benefits included the ability to turn the tractor in its own length within a 10ft turning circle.

The new 12-20 was designed with a large tubular radiator plus a fuel tank located at the front and the driver at the rear of the tractor, but the transmission was placed in front of the engine where it delivered power to each track.

The engine position behind the transmission placed it just in front of the driver and, as there was no cover over the engine, the obvious disadvantage of this layout was that being close to the engine would have exposed the driver to noise and heat.

Driver visibility

Bullock tractor design characteristics appear to have included positioning the cylindrical radiator and the fuel tanks where they blocked some driver visibility.

On the 35-50 model, the main problem was the transversely positioned fuel tanks – a large one for paraffin and a smaller tank for petrol – which blocked some of the rear view, and on the 12-20 the forward view was partly obscured by the 35-gallon tubular cooling unit.

The model numbers followed the American convention of indicating the power output from the engine and at the drawbar, and on the 12-20 the power unit, made by Waukesha, had four cylinders with spark ignition and the rated output was developed at about 900rpm engine speed.

The power was delivered through a gearbox with one forward speed and one in reverse and the maximum in each direction was 2.25mph.

America’s tractor manufacturers enjoyed a big sales increase during World War 1, and this was approaching its peak in 1916 when the 12-20 tractor arrived.

The Bullock company was able to share in the expansion, and they also exported some of their 12-20 tractors to the UK, in addition to the tractor bought for the army’s Landship project.

The number of Bullock Creeping Grip tractors sold here appears to have been very small, partly because of the general preference for wheels rather than tracks, but also because the 12-20 was expensive by UK standards.

The Bullock company’s agent in London arranged for a 12-20 tractor to take part in the large-scale tractor demonstration held in Scotland in 1917, and the price quoted at that event was £435 plus the shipping costs from America.

At the same event, a British-built Weeks Dungey tractor with wheels, powered by apparently the same type of Waukesha engine as the 12-20, was available with a £295 list price including free delivery from a local dealer.

After the war ended in 1918, the tractor market entered a period of intense competition encouraged by Henry Ford’s aggressive price cutting policy for his mass-produced Fordson, and dozens of small to medium scale tractor companies were forced out of business in the US and in Britain.

The Bullock company had already made a number of design improvements to the 12-20, including engine modifications that increased the power to 15hp at the drawbar and 25hp at the flywheel, but in 1920 Bullock announced a merger with the Franklin company which was also a tracklayer specialist.

The merger was the end of the road for Bullock Creeping Grip tractor production after less than 10 years, and it also appears to have been the end of tractor manufacturing for the newly merged Franklin-Bullock company.