Despite the disadvantages, wood has provided fuel for tractors on many thousands of farms, and it has also been used in road vehicles including trucks and buses.

The equipment was used mainly in wartime when normal fuel supplies were not available, starting with small scale tractor use on farms toward the end of the 1914-18 war.

See also: Whatever happened to… single-cylinder Marshalls?

The main period for wood-fuelled power farming was during World War 2, especially in mainland Europe where fuel shortages were particularly severe, and the government in wartime Germany passed a law that made it illegal to sell a new tractor that was not equipped with the government’s officially approved conversion kit allowing the engine to use fuel produced from wood.

Some UK farmers fitted their tractors with one of several kits that were available from machinery dealers in order to supplement the World War 2 fuel rations, and there were also some tractors working on fuel from wood in Australia where there were wartime fears that oil imports might be blocked by the Japanese navy.

The fuel-from-wood process also has a long history of providing power for small-scale manufacturing industry situated in rural areas where trees are plentiful.

Suitable trees

The recipe for turning wood into tractor fuel starts with choosing the most suitable trees. Official German recommendations put beech at the top of the list, followed by birch and other hardwoods, but conifers were less popular as the tar content could decrease engine reliability and increase servicing requirements.

The wood must be kept dry during storage as a low moisture content was essential, with 15% suggested as the recommended limit.

The next stage in the preparation process was to cut the wood into small pieces measuring about 7cm, which could be used to produce the fuel to power a specially converted tractor engine.

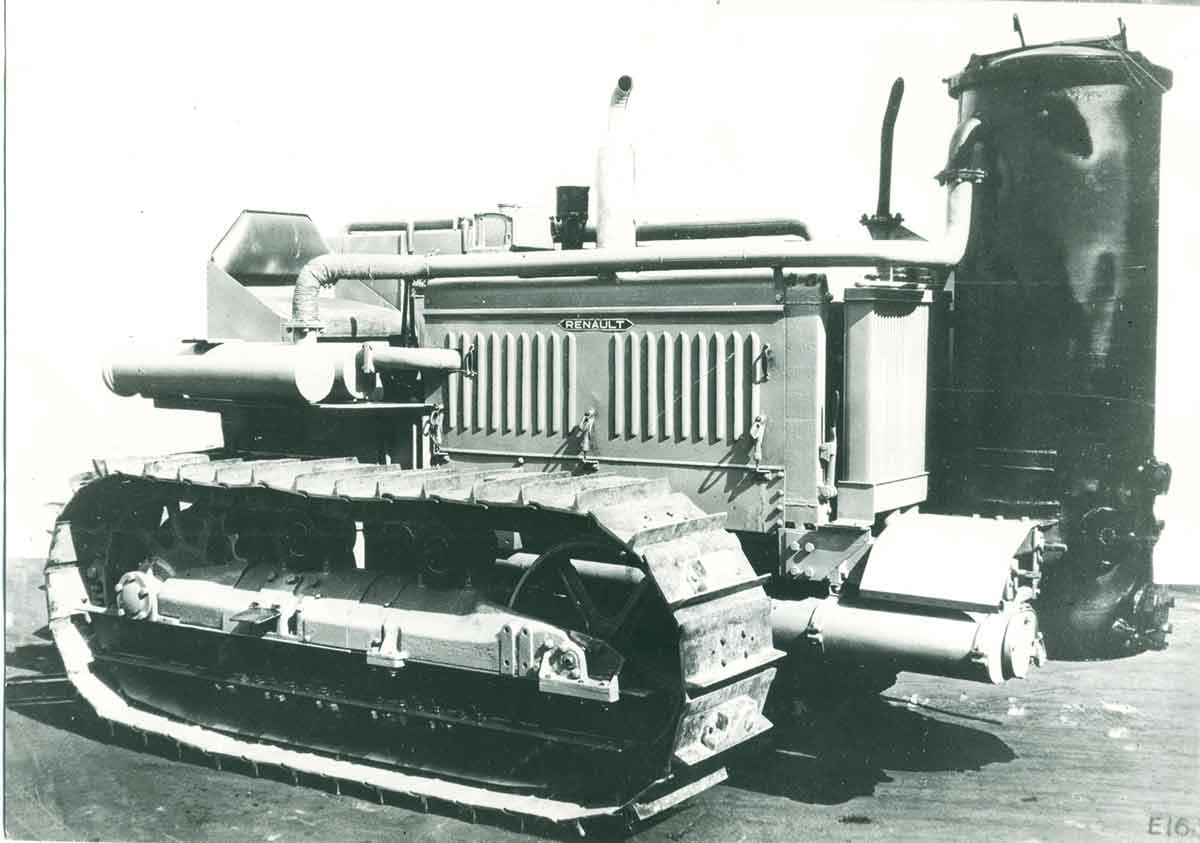

The fuel production equipment was attached to the tractor and was carried in a container which was large, usually cylindrical in shape and consisted of two main sections which both carried some of the wood, with heat produced from a wood fire burning in the smaller base section and passing into the wood blocks carried in the upper compartment.

When wood is heated sufficiently it produces a gas, and in an open fire with an air supply the gas is allowed to burn with a flame to warm a room.

In the special fuel production container, there is no access for incoming air and oxygen, and gas released by the heat from the fire is delivered to the tractor engine’s combustion chambers where it is used as a replacement for the normal liquid fuel to power the engine.

‘Producer’ gas

Gas generated by the heating process on a wood-fuelled tractor is known as ‘producer’ gas or wood gas. It could be used in the spark ignition engines that powered most of the tractors on farms during World War 2, as well as in the few diesels that were available then, and it can also fuel other types of power units including gas turbines and fuel cells.

Producer gas is a mixture of nitrogen plus carbon monoxide, carbon dioxide and a small amount of hydrogen, and it was welcomed by farmers when it enabled them to continue using their tractors while the usual fuel supplies were not available.

Significantly, however, the fuel’s disadvantages meant that nearly all the producer gas kits were removed from tractors and other vehicles as soon as normal fuel supplies became available again after the war.

The biggest problem was a reduction in power output when switching from petrol or paraffin to producer gas, and the power loss was typically 15 to 20%, but could be much higher when the wood used as fuel exceeded the recommended moisture level.

Starting from cold was a slow process, typically taking 15- 20 minutes to clear ash from the previous fire, refill the generator with wood, light the fire and produce sufficient heat to start the engine.

Refills

When the tractor was working for long periods, the driver could expect to stop every two or three hours to refill the gas generator with wood and also make up the fire, and refuelling needed special care because of the fire risk when hot ashes and embers were being handled while the tractor was working in hay or harvesting a grain crop.

Another reason for the wood-burners’ unpopularity was their size, which blocked some of the visibility from the driver’s seat.

The capacity of some of the larger models was up to 300 litres, and it was usually mounted on the side of the tractor, adding to the overall width when travelling on the road or through a narrow gateway.

Because of their unpopularity on farms, very few tractors have survived from the World War 2 period complete with their producer gas kits.

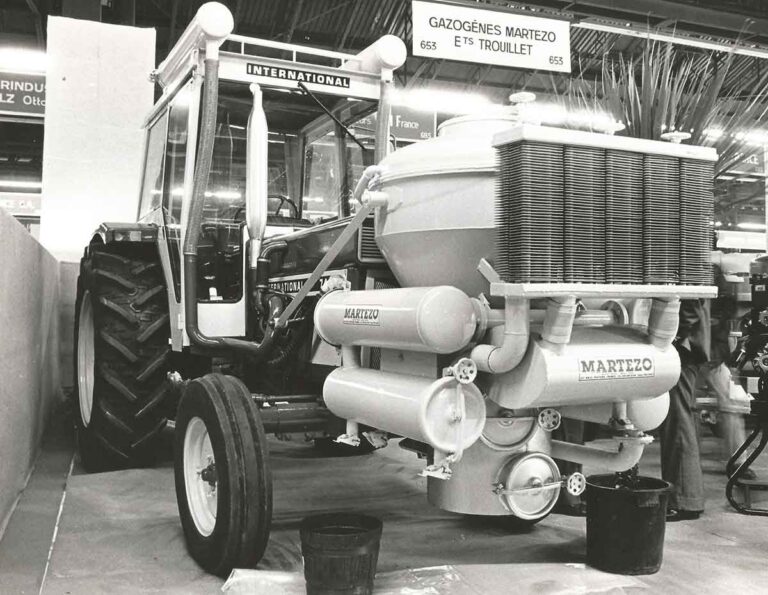

In spite of the lack of popularity for the wood-for-fuel kits’, several companies in France tried to revive the idea in the late 1970s and early 1980s.

They designed updated versions of the generator kits to provide affordable home-produced fuel for farms in developing countries which lacked oil resources but had plenty of timber available, but the kits attracted little interest and the project was soon abandoned.