At its Future Farm Days event, Lely introduced new products and upgrades around its autonomous livestock equipment

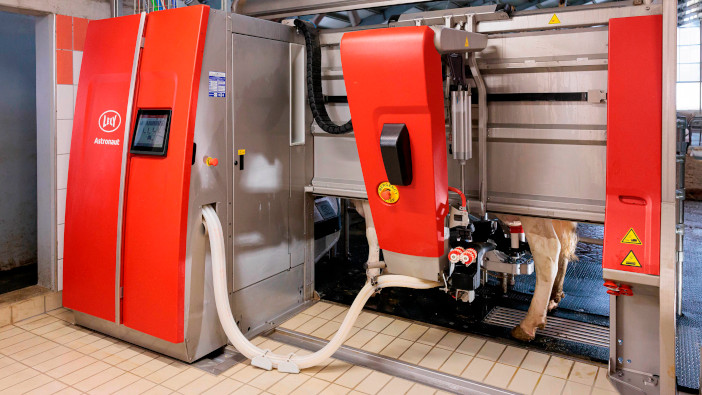

Headlining the launch was a series of upgrades to the company’s A5 Astronaut robotic milker, of which there are now 29,000 units working globally since its introduction in 2018.

Dubbed the A5 Next, the unit works on a new operating system, which enables upgrades to be installed at the push of a button and, according to the company, will lay the groundwork for fully remote servicing in the future. Field trials conducted by Lely have reportedly shown reduced alarms and less downtime with this updated system, leading to a 10% increase in milkings between alerts. A5 Next can also diagnose issues within the system and alert the grower if a technician is required.

Onto the hardware, and the new Astronaut will include a redesigned robot arm, with the 2+ teat detection system. This combines lasers and cameras to enhance visibility, as well as improve attachment times and reportedly reduce stress during the first milking. As milking occurs, the arm will also monitor teat health and size.

Lely has also integrated a new automatic milk filter, which will eliminate the need for filter socks. It uses a back-flush cleaning system along with a stainless-steel membrane. According to the company, one filter can work with up to four robots and will save operators money and time in the long run.

Available now, the system has also been future-proofed and can be linked to electronic ear tag identification to align with UK regulations, as this will be mandatory for all newborn calves from 2027. Finally, it also features Milk for Use, which uses a low-pressure nozzle to reduce foam and divert colostrum into one of four sealed buckets to protect against flies.

Protecting data

For operators using the Horizon system with an A3 Astronaut or a newer model, Lely has also introduced the Lely Hub. This is said to offer advanced data protection, acting as a shield between the robot and the farmer’s computer or mobile device.

A secure server processor protects farm data from cyberattacks, power outages and hardware failures, with remote backups to a secure data storage and the ability to remotely monitor, support and upgrade the system.

When power is lost, an external battery keeps Horizon active to safeguard data, while if the system is hacked or crashes, the Hub can reportedly quickly recover and restore data.

Lely Hub will be rolled out from 2026, with support for up to eight robots and Vector users. The company plans to make it compatible with more of its systems in the future.

Central control

Central control

Also launching commercially next year, the Lely Max system is a central hub for large-scale dairies, capable of monitoring and controlling up to 18 robots.

The system centralises cleaning, cooling and milk pumping to reduce labour requirements and free up space on farms, as current systems require a robot room for every two robots.

Milking and cleaning and performed independently with separate lines, meaning that robots can remain operational during routine servicing and cleaning. The company estimates that this will increase milk capacity by around 5% due to shorter cleaning cycles and reduced cow waiting times.

Chemicals are stored in a fire-proof side room, including colour-coded containers and no-touch levers to improve safety, while multiple vacuum pumps ensure continuity even in the case of a failure.

Speaking at the event, André van Troost, CEO, said: “Business continuity is crucial for our farmers. Both in terms of the reliability of the milking processes and digital resilience. Astronaut Max and Astronaut A5 Next are designed to provide farmers with stability in their dairy operations and offer future-proof automatic milking solutions.

“Furthermore, with the increase in digital services on the farm, data security is essential. Lely Hub supports our farmers by improving digital safety between Lely solutions and the internet.”