Pete Olds and his father Len grow 300 acres of combinable crops but were finding that their grain processing plant was struggling to cope with the 4,000 tonnes of wheat and barley each year.

The pair worked with McArthur BDC – who had installed the previous unit – to install a new plant last year, which was operational in time for the 2023 harvest.

“Due to the improved efficiency of the new plant, it is already delivering a return on investment,” said Pete. “Our previous 25t drier, even in the hot summer of 2022 was averaging just 6.5tph, whilst our new Svegma 15tph SV3/3 continuous flow drier, manufactured by Akron, delivers a significant increase in productivity. It has been hitting 20tph when the crop has been drier, which we’re very pleased with.”

Before investing, the Olds had considered a range of options, including second hand units. However, there were issues around dismantling and reassembling an existing machine. As well as this, any machine had to fit within their existing shed and require a maximum electric supply of 100amps.

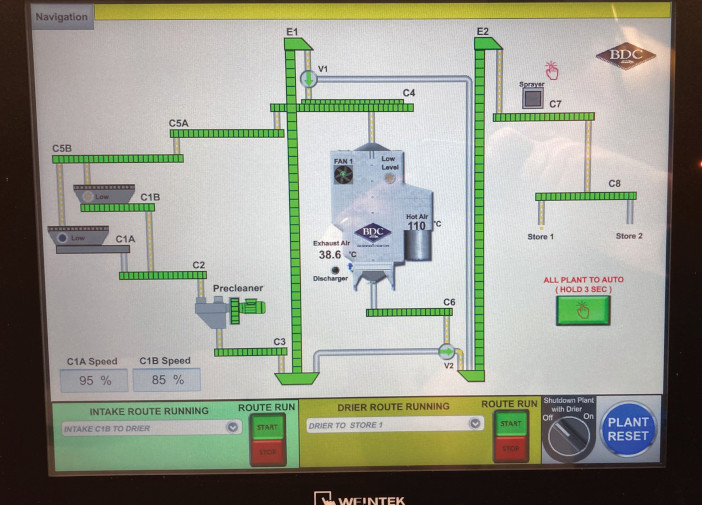

Alongside the new drier, Skandia handling equipment was installed, made up of two 40tph I-Line chain and flight trench intake pits, six L-Line conveyors, two L-Line belt and bucket elevators and a dust and chaff remover. As well as this, a moisture monitoring system was installed with a PLC control panel for remote management.

“The combined McArthur BDC team presented us with a 3D CAD drawing which provided great insight into exactly how the different elements of the plant fitted together. We could see exactly what they were putting together for us,” explained Pete.

The monitoring system analyses the moisture content of the crop going in and out of the drier. As the Olds receive grain from multiple customers, this can vary regularly. If the moisture content is outside of the predefined levels, the system sends alerts to them, as well as warnings for blockages, empty intake pits or any other issues.

“Speed of throughput and ease of use have been critical factors for us. It was a challenging wetter harvest and as good a year as any to upgrade our drying capabilities,” continued Pete. “We used to have to stockpile wet corn temporarily outside before it got to our previous drier. Sometimes we have four combines harvesting and sending corn into us, so the previous drier had become a real pinch point for us.”

“The intake pits are ideal and provide a buffer for us to operate the drier. In fact, the drier is so swift, we need to get a decent amount of grain in before we start up the plant! We haven’t used any outside storage this year.”

He added that McArthur BDC was very flexible during the design stage, working closely with the Olds as the pair extended the building infrastructure. This enabled them to handle installation at their own pace and have the unit ready to go before the first load of grain arrived.

“The new plant, which we see as having a 20-plus years lifespan, is working really well for us and has certainly made harvesting easier. We had been used to drying grain around the clock for days on end to keep up with the combines, but for harvest ’23 we only had to dry past midnight a handful of times. We were able to get some much-needed sleep!” concluded Pete.

For more information go to www.mcarthurbdc.co.uk