Rise in demand for DeLaval milking robots has led to an increase in production of more than 20 percent. DeLaval has seen a surge in demand for its VMS™ V300 model and the new VMS™ V310.

“As farmers look to drive milking efficiencies, we have seen a much higher than expected demand for robots which has led us to increase production much faster than we anticipated,” says AMS cluster solution manager, Edouard Alix.

The new VMS™ V310 attaches teat cups 50 per cent faster than the previous model and milking capacity is up by 10 per cent to a potential 3,500 kg of milk a day, yet running costs are lower. “We see these efficiencies as the main driver for farmers choosing to switch to robots, or update existing ones, and we anticipate demand to remain strong as a result,” he adds.

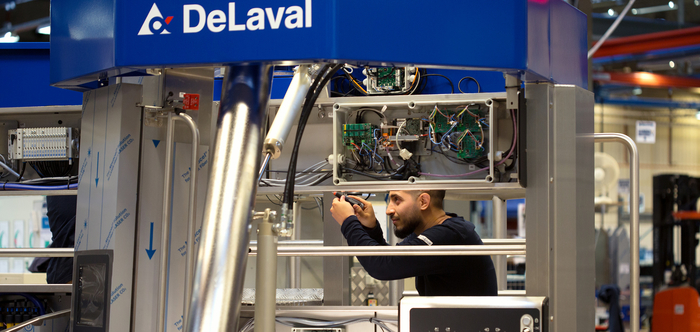

The uplift follows DeLaval doubling robot production in 2018 and has been achieved despite the compromises brought by the Covid-19 pandemic. Strict safety measures were implemented to protect staff and ensure production could continue to meet demand. “We have been able to make adjustments to the production line to both protect our staff and increase the number of robots being produced. This has led to an increase of more than 20 percent with lead time remaining consistent throughout,” he says.

DeLaval launched the VMS™ V300 in 2018, and the new DeLaval VMS™ V310 model with the unique RePro™ module was added to the range in 2019. The module adds progesterone testing to enable faster heat detection and better overall cow management. “This technology gives the farmer more data faster which means no more waiting for vets or physical signs of heat. Instead, the robot detects that the cow is in heat based on a milk sample which is taken automatically when she is milked,” he says.